Have you ever wanted to create bold and colorful designs that last on fabric?

Sublimation printing is a game-changer for modern apparel. It allows you to transfer high-quality images onto polyester materials with heat and pressure. Unlike other printing methods, the ink becomes part of the fabric, so the design won’t crack or fade.

Whether you’re starting a business or making custom clothing, sublimation offers endless creative possibilities. This article will guide you through the basics, tools, and tips for success.

Essential Tools for Sublimation

A sublimation printer is necessary for printing designs with sublimation ink. This printer uses special ink that turns into gas when heated. Regular printers cannot be used for this process.

Transfer paper holds the design before it is applied to the fabric. A heat press machine is needed to apply the right amount of heat and pressure. Polyester-based fabric is the best material for sublimation printing.

Sublimation blanks, such as t-shirts, hoodies, and tote bags, are specially made to work with this process. These blanks have a high polyester content, ensuring that the ink bonds properly for vibrant and lasting results.

Step-by-Step Printing Process

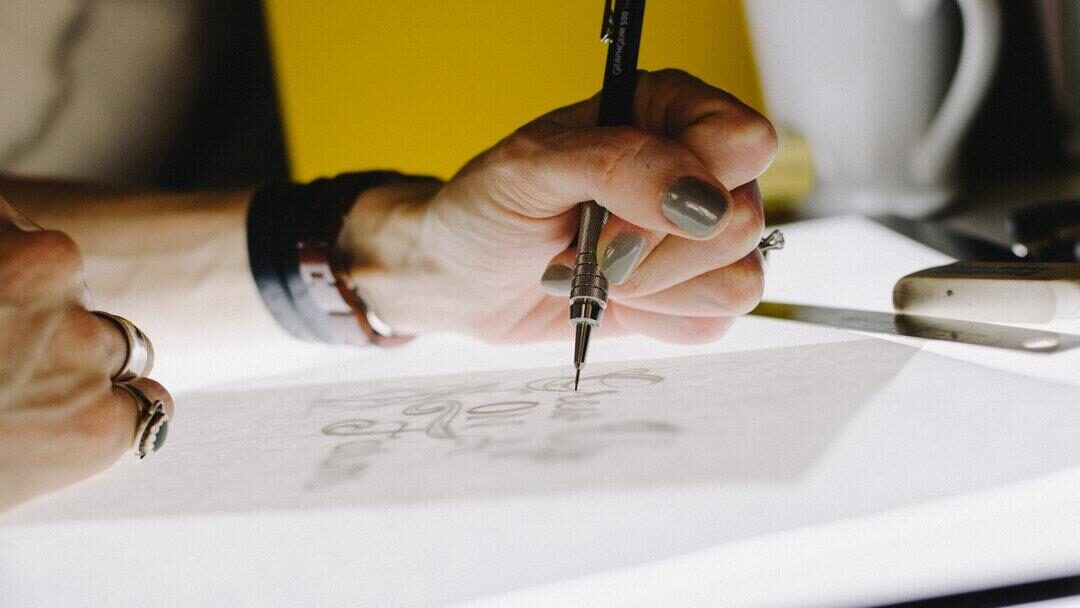

The design is created using graphic design software. The image is then printed onto sublimation paper with sublimation ink. The printed transfer is placed face-down on the fabric for pressing.

A heat press machine is set to the correct temperature and pressure. The heat activates the ink and allows it to bond with the fabric. After pressing, the fabric is allowed to cool before the paper is removed.

Best Fabrics for Sublimation

Polyester fabric produces the most vibrant and durable sublimation prints. The ink bonds directly with the polyester fibers, creating a permanent design. Higher polyester content leads to better results.

Polyester blends can also be used, but the colors may not be as strong. Light-colored fabrics work best because sublimation ink is transparent. Dark fabrics do not absorb the ink properly, making the design hard to see.

Common Mistakes and How to Avoid Them

Using the wrong fabric can result in dull or incomplete transfers. Polyester content should be at least 65% for the best results. Fabrics with too much cotton do not bond well with sublimation ink.

Applying incorrect heat and pressure can affect the final print. Each type of fabric may require different settings for the heat press. Following manufacturer guidelines helps to avoid transfer errors.

Tips for High-Quality Prints

High-resolution images help to create sharp and detailed designs. Low-quality images may result in blurry or pixelated prints. Designs should be properly sized before printing.

Keeping the heat press clean prevents stains on the fabric. Dust or ink residue can cause unwanted marks during pressing. Regular printer maintenance helps to prevent ink clogging.

Sublimation Printing Brings Your Designs to Life

Sublimation printing is a powerful way to bring your creative ideas to life. It gives you the freedom to design unique apparel with sharp details and bright colors. With the right tools and techniques, you can produce stunning prints that stand the test of time.

Whether you are a beginner or an expert, there is always something new to learn. Keep experimenting and improving your skills to create high-quality, professional-looking designs.

Did you learn something new from this article? If so, be sure to check out our blog for more educational content.